Remove those subgroups from the calculations.

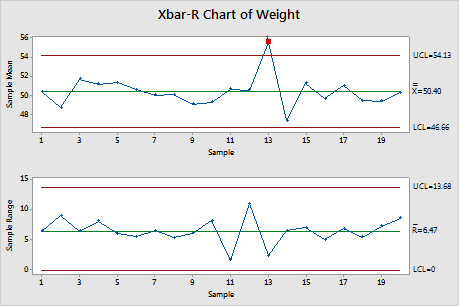

Once you have constructed your X-bar/R charts, you’ll need to interpret what they are telling you about your process. Do not artificially subgroup data to dampen or reduce apparent variation. There must be some logic and rationale for the subgroups. The purpose of subgrouping is to minimize the within -sample variation so as to maximize the ability to see between -sample variation.ĭo not create subgroups for convenience. Rational subgrouping is the process of selecting a subgroup based upon logical grouping criteria or statistical considerations. If both charts are now in control, extend the control limits for ongoing monitoring.Īn important consideration in using X-bar/R charts is the selection of an appropriate subgroup or sample size.If the X-bar chart is not in control, take appropriate action and investigate.If the R chart is in control, calculate control limits for the X-bar chart.If the R chart is not in control, take appropriate action and investigate.After 20 or more sets of measurements, calculate control limits for the R chart.Plot the data (both the averages and the ranges).Calculate the average and range for each subgroup.Collect your data (take a set of readings at each specified interval of time).Determine an appropriate subgroup size and sampling plan.Here are the steps for constructing the X-bar/R charts. For example, if your sample size was 7, you would use 0.419, 1.924 and 0.076, respectively, for A2, D4, and D3. Here is the table where the value of the constants are taken from based on the size of the subgroup or sample. In the formulas above, you see mention of the constants A2, D4, and D3. Displays changes in the within subgroup variationīelow are some further descriptions and formulas for calculating the values on the X-bar/R charts.Control limits, related to +/- 3 standard deviations, are calculated using the Range chart (Rbar).Useful for identifying special cause changes to the process mean (Xbar).Plots the mean (average) of each subgroup to see between -sample variation.Consists of two charts displaying central tendency and variability.The Xbar & R chart is the most commonly used control chart.Here is some further information about the charts. The X-bar chart measures between-sample variation (signal), while the R chart measures within-sample variation ( noise ). X-bar/R charts are a pair of control charts where continuous or variable data is collected in rational subgroups. For special cause variation, the correct response is to try and find the root cause of the unexpected variation and either incorporate or eliminate the cause depending on whether the special variation improved or degraded the process.

For common cause variation, the action is to work on improving the process by reducing the variation or moving the process average. The actions one takes will depend on the type of variation. The control chart was developed to help distinguish between the two. Shewhart defined his concern in terms of assignable or special cause and random or common cause variation. This constant tampering with the process without knowing whether the variation was due to an assignable cause or the natural random variation existing in all processes was a problem. While employed at Western Electric and Bell Laboratories, Shewhart became aware that operators were frequently adjusted their processes when the process appeared to vary from the nominal value. Shewhart, an American physicist, engineer, and statistician, who is sometimes referred to as the father of statistical quality control. In this article, we will discuss what the X-bar/R charts are, how they are constructed, their benefits, and best practices for using them. But is the variation common to the elements of your process or something special? If your data is continuous or variable data, the X-bar and R charts will tell you. The data you collect from your process will vary. Definition of X-Bar and R Charts: « Back to Glossary IndexĪll processes vary.

0 kommentar(er)

0 kommentar(er)